mcPolymer

The software mcPolymer is located in the interdisciplinary field of polymer reaction engineering, which deals with the sustainable development, planning, and implementation of polymerization processes.

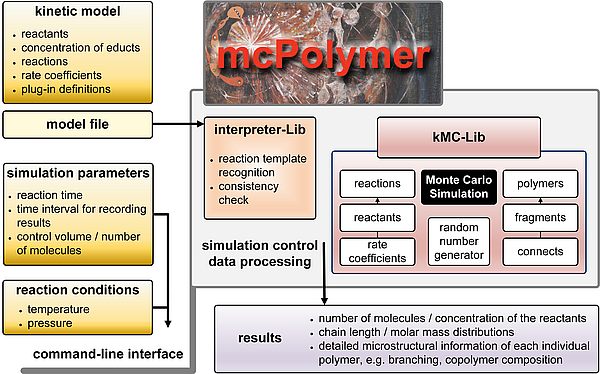

Kinetic Monte Carlo (kMC) simulations provide access to detailed information on the microstructure of polymers, such as molar mass distributions (MMDs), branching levels and types of branches, copolymer composition, and conversion-time data, as long as the kinetic model contains all relevant elemental reactions. The open source simulator mcPolymer is based on the Monte Carlo simulation technique and published under the GNU General Public License (GPL), which is unique in the field of polymerization modeling.

Simulations with mcPolymer are based on the concept of fundamental reaction templates. Thus, mcPolymer is very versatile and applicable to very different types of polymerizations. mcPolymer is mainly applied to model radical polymerizations, e.g., simulations of reversible deactivation radical polymerizations, or simulation of acrylate polymerizations with backbiting and transfer to polymer reactions. A kMC model for acrylate radical polymerization may consist of more than 40 elemental reactions, which proceed in parallel, and the same number of kinetic coefficients. Since the concentrations of reactants may cover eight to nine decadic orders of magnitude, 1010 to 1011 molecules have to be accounted for. The sophisticated modular structure of mcPolymer allows for the integration of the simulator in complex simulation environments.

- The file mcPolymer-documentation_and_tutorial.pdf describes how to use the program and presents the simulation results based on a simple example of styrene polymerization.

- All implemented reaction templates and their application in the provided examples are listed in a table (file mcPolymer-reaction-templates.pdf).

- Published kinetic models are provided in the repository. These contain the kinetic model (e.g., BA_HT.mcPolymer). The corresponding readme file (e.g., readme_example_BA_HT.md) contains the command line calls.

- atrp: styrene bulk polymerization, Atom Transfer Radical Polymerization (ATRP)

- ba: butyl acrylate (BA) polymerization

- ba-ht: butyl acrylate (BA) polymerization at high temperature

- nmp: nitroxide-controlled MMA/styrene copolymerization

- styrene: styrene bulk polymerization, nitroxide controlled radical polymerization (NMP)

- raft: reversible addition - fragmentation chain transfer (RAFT) polymerization: cumyl dithiobenzoate mediated methyl acrylate polymerization

- styrene: styrene bulk polymerization

- vac: vinyl acetate (VAc) polymerization

Documentation and Tutorial

Reaction templates

Examples

Download and Build mcPolymer

AI-based forecasting of polymer properties for high-temperature butyl acrylate polymerizations

J. Fiosina, P. Sievers, M. Drache, S. Beuermann

ACS Polymers AU 4, 438 (2024)

doi.org/10.1021/acspolymersau.4c00047

Reverse Engineering of Vinyl Acetate Polymerizations by Genetic Algorithm-Based Multi-Objective Optimization

J. Fiosina, P. Sievers, M. Drache, S. Beuermann

Frontiers in Artificial Intelligence and Applications | Volume 392: ECAI 2024 - 27th European Conference on Artificial Intelligence, 19–24 October 2024, Santiago de Compostela, Spain – Including 13th Conference on Prestigious Applications of Intelligent Systems (PAIS 2024)

doi:10.3233/FAIA241068

Reverse engineering of vinyl acetate polymerizations by genetic algorithm-based multi-objective optimization

J. Fiosina, P. Sievers, M. Drache, S. Beuermann

ChemRxiv 2024

doi.org/10.26434/chemrxiv-2024-kq3wd

Reverse Engineering of Radical Polymerizations by Multi-objective Optimization

J. Fiosina, P. Sievers, G. Kanagaraj, M. Drache, S. Beuermann

Polymers, 16, 945 (2024)

doi.org/10.3390/polym16070945

und

DOI: 10.20944/preprints202402.0199.v1

Polymer Reaction Engineering meets Explainable Machine Learning

J. Fiosina, P. Sievers, M. Drache, S. Beuermann, ChemRxiv (2023)

doi: 10.26434/chemrxiv-2023-5vd8h

und

J. Fiosina, P. Sievers, M. Drache, S. Beuermann, Comput. Chem. Eng. 108356 (2023)

doi:10.1016/j.compchemeng.2023.108356

Kinetic Monte Carlo Simulations as a tool for unraveling the impact of solvent and temperature on polymer topology for self-initiated butyl acrylate radical polymerizations at high temperatures

J. Mätzig, M. Drache, G. Drache, S. Beuermann, Macromol. Theory Simul., eingeladener Artikel, 2300007 (2023)

doi:10.1002/mats.202300007

Modeling complex semi-batch vinyl acetate polymerization processes

A. Feuerpfeil, M. Drache, L.-A. Jantke, T. Melchin, J. Rodríguez-Fernández, S. Beuermann, Ind. Eng. Chem. Res. 60, 18256 (2021)

doi.org/10.1021/acs.iecr.1c03114

Ab initio Kinetic Monte Carlo Simulation of Seeded Emulsion Polymerizations of Styrene

M. Drache, K. Brandl, R. Reinhardt, S. Beuermann, Phys. Chem. Chem. Phys. 20, 10796 (2018)

DOI: 10.1039/C7CP07768H

Experimentally calibrated random walk of branched polymers: a pragmatic approach

B. Hosemann, M. Drache, S. Beuermann, Macromol. Theory Simul. 25, 508 (2016)

DOI: 10.1002/mats.201600067

Advanced kinetic parameter fit applied to radical copolymerizations

B. Hosemann, M. Drache, S. Beuermann, Macromol. Symp. 370, 17 (2016)

Modeling of Branching Distributions in Butyl Acrylate Polymerization Applying Monte Carlo Methods

M. Drache, B. Hosemann, T. Laba, S. Beuermann, Macromol. Theory Simul. 24, 301 (2015)

DOI: 10.1002/mats.201400081

Simulating Controlled Radical Polymerizations with mcPolymer—A Monte Carlo Approach

M. Drache, G. Drache, Polymers 4, 1416 (2012)

10.3390/polym4031416

Modeling the Product Composition During Controlled Radical Polymerizations with Mono- and Bifunctional Alkoxyamines

M. Drache

Macromolecular Symposia 275-276, 52 (2009)

Modeling RAFT polymerization kinetics via Monte Carlo methods: cumyl dithiobenzoate mediated methyl acrylate polymerization

M. Drache, G. Schmidt-Naake, M. Buback, P. Vana

Polymer 46, 8483 (2005)